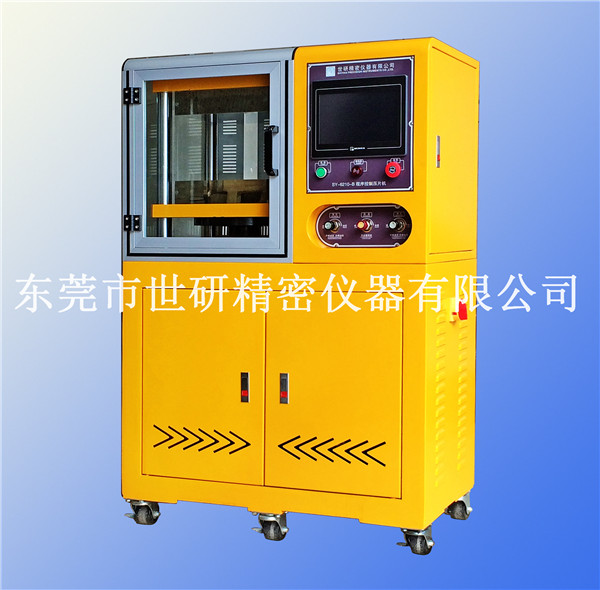

产品详情

Usage Description:

The raw materials are placed in the mold and sandwiched between the electric heating plates of the tablet press to apply pressure and temperature, forming the raw materials for testing and serving as the basis for mass production of ingredients in the factory. This machine is equipped with a PLC program controlled color touch screen, and the human-machine interface operating system can set pressure, temperature, time, and exhaust frequency. The vulcanization process is displayed and monitored in real-time, and all molding programs are automatically completed.

Typical applications:

■ Detection of gel (fish eye), black spot, stain, etc. of raw materials

Raw material tablet pressing, color matching, mixing, and sample preparation

Physical property testing

Material research and development

Total pressure | 20/30/50 tons(optional) |

Temperature range | Room temperature-300℃ or Room temperature-400℃/500℃ |

Temperature accuracy | ±2℃ |

Heating method | Electric heating |

Controller | PLC control, 10-inch color touch screen display |

Size of the pressing plate | 300×300mm,Other sizes can be customized |

Distance of pressing plate | 80mm ,Other sizes can be customized |

Working area | Two working areas, the upper area has heating and cooling functions at the same time, and the lower area is cooling. |

Cooling method | water cooling. |

Exhaust times | Settable |

Oil pressure system | Dual speed function, fast mold closing and slow mold locking; It has the functions of automatic pressure maintaining compensation and delayed shutdown of oil pump. |

Security protection | Self-locking the safe and visible door. All the operating instructions or actions of electronic control system will be cut off instantly when opening toughened glass door. |

Volume | About 920×470×1500 (L×W×H) mm |

Power supply | 3∮,AC380V,Three-phase and five-line power supply |

Weight | About 720 kg |

版权所有(C) 东莞市世研精密仪器有限公司