产品详情

Description

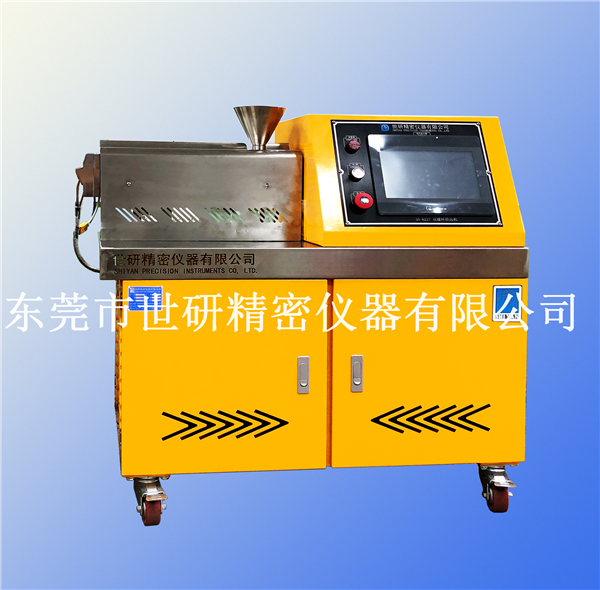

This machine, appropriate for the mixing processing experiment of engineering plastics, modified plastics, waste plastics and color masterbatch etc., is featured by plasticizing homogeneity, color proofing and filling modification.

Typical Application

<Filling modification

<Blending modification (rubber blending, plastic alloy)

<Processing after exhaust and devolatilization

<Reactive extrusion

<Function of maternal

<Glass fiber (carbon fiber) reinforced

<Metal, ceramic powder masterbatch

Screw diameter | 16. 18 (optional) |

Length diameter ratio | 25:1, other length diameter ratio (10~30 times) optional |

Screw form | Parallel and rotating in the same direction, modular twin screw |

Temperature range | Room temperature~300 ℃ or customized |

Control accuracy | ±2℃ |

Controller | PLC controller type |

Screw material | W6Mo5Cr4V2 high-quality alloy steel or customized other materials. |

Compound mode | The compound mode of the screw suite is building block spiral.The material barrel is a multistage combination, which can be opened and closed. |

Heating zone | Multi zone temperature control for material barrel and machine head, and installation of stainless steel safety cover |

Cooling facility | Air cooled or water-cooled |

Handpiece | Flange interface, which can be connected to the mold for extrusion tests such as film blowing, casting, pipes, sheets, profiles, etc |

Driving power | 1-2.2KW |

Power supply | 3∮,AC380V, 50Hz three-phase & five-wire |

Volume | ≧800×550×600 (L×W×H)mm |

Weight | ≧150 kg |

Copyright (C) Dongguan Shiyan Precision Instrument Co., Ltd